As featured in AAAA Magazine – July 2022

The key problem lies in the difficulty of testing batteries, and this applies to repair shops, retail outlets, and service garages. There is a significant shortfall in a reliable method of estimating the state-of-charge, which is based mostly on voltage and charge counting. Assessing capacity, is the leading health indicator of a battery! Measuring the open circuit voltage and checking the internal resistance do not provide conclusive evidence of battery state-of-health.

A dead battery is easy to check and most testers are 100 percent accurate. The challenge comes in evaluating a battery in the 80–100 percent performance range while in use. Most service and repair workshops struggle to introduce good battery test procedures.

When testing a battery and trying to determine the state of health you must consider:

The top indicator of a battery health is capacity(energy storage). A new battery should deliver 100 percent of the rated capacity. This means a 10Ah pack should deliver Ten amps for 1 hour. If the battery fails to perform after 20 minutes, then the capacity is only 33 percent. Capacity defines end of battery life.

Lead acid starts at about 85 percent and increases in capacity through use before the long and gradual decrease begins Lithium-ion starts at peak and begins its decline immediately, but at a very slow pace.

Knowing when to replace a battery is a difficult, battery problems only become apparent with increased breakdowns, which may be caused by a lack of battery maintenance.

Battery replacement depends on the application. Using battery Analysers typically set the replacement threshold at 80 percent capacity. In some applications you can keep the battery longer than others and cost decisions need to be made in different situations.

More than 40 percent of all roadside car failures are battery-related, and 30% involve either a discharged or defective battery. Additionally, only a few starter batteries reach the average age of five years. The average car is driven 13km per day and mostly in cities. The most common reason for battery failure is undercharge or sulfation. Battery failure in warranty period is uncommon, driving habits are the main culprits.

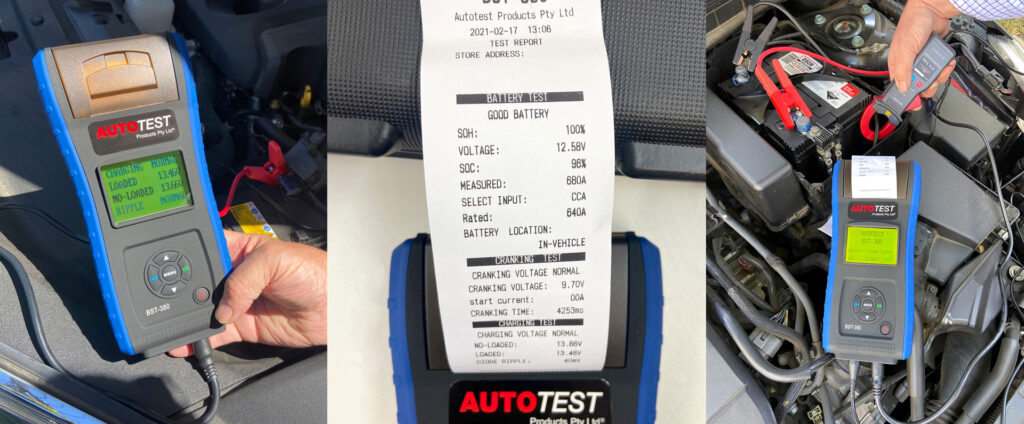

The AutoTest® Battery System Tester uses the adjustable load test to decide whether your battery is still usable or needs to be replaced. These testers measure the voltage drop when a voltage load that is half the battery’s CCA rating is used. The load is applied for about 15 seconds and the voltage drop is measured. If the drop reading does not fall below 9.6 volts, then your battery is ideally conditioned, and is therefore, considered good.

This accurate method of testing is exactly how the AutoTest® Battery System Tester evaluates a battery. It not only gives a complete view of battery health, but is a conveniently portable, easy to use battery analysis tool designed for automotive service, fleet maintenance and breakdown assist diagnostic use. Taking the guess work out of battery diagnosis alerting you to replace batteries before they fail.

The Battery System Tester is a professional quality unit that tests all 12V auto batteries, including new auxiliary batteries for hybrids.

It uses advanced conductance testing technology to easily, quickly and accurately measure the actual cold cranking amps capability of the vehicle starting battery, the health of the battery itself, and common faults in the vehicle starting system and charging system. It can help maintenance personnel to identify problems quickly and accurately, thus leading to efficient vehicle repair.

See our Battery Tester and Clamp Set.

This set includes a Current Clamp which directly measures the actual CCA (cold cranking amps). This significantly increase the accuracy of the test.

Test Functions:

Optional Extras: