Road transport is a source of air pollutants which can have adverse effects at various scales. The air pollutants which are currently causing greatest concern in terms of local air quality, primarily because of their impacts on human health, are airborne PM, NO2 and ground-level ozone5. Road transport is an important contributor to all three. Emissions of nitrogen oxides (NOx) from road vehicles are also implicated in regional phenomena such as acidification, eutrophication and loss of biodiversity, as well as the formation of secondary PM in the atmosphere. Moreover, road transport is a major source of the greenhouse gases carbon dioxide (CO2), methane (CH4) and nitrous oxide (N2O).

The significance of road transport as a source of air pollution can be illustrated by reference to sectoral emissions for the EU-27 countries, based on submissions to the UNECE Convention on Long-Range Transboundary Air Pollution (CLRTAP). Road transport is a significant contributor to NOx emissions (41% in Europe) and is also a major contributor to PM emissions. In urban areas its impact is even greater due to the density of the road network, the volume of traffic, and the close proximity of the population to the emission source.

Legislation and strategies to reduce exhaust emissions from road vehicles have been in place for some time. Calculations have established that emissions of regulated pollutants from road transport have been reducing as controls on vehicles and fuels have tightened. However, in many urban areas the concentrations of NO2 and PM10 (particulate matter with an aerodynamic diameter of less than 10 μm) still frequently exceed health-based limits and are not decreasing.

The importance of NO2 and particulate matter is explained in more detail below.

Nitrogen dioxide

NO2 is an irritant and oxidant which can damage cell membranes and proteins. It has been linked to a range of adverse health effects, including asthma and cancer, but the most consistent association has been found with respiratory outcomes.

NO2 is predominantly a secondary pollutant, its major atmospheric source being the oxidation of NO emitted from combustion sources – notably road vehicle exhaust. However, some NO2 is emitted directly from vehicles, and this is commonly referred to as ‘primary NO2’. Emissions of NOx from vehicle exhaust are regulated at type approval, but NO2 emissions per se are not.

Analyses have indicated that a significant proportion of ambient NO2 must be emitted directly from vehicle exhaust, and that the direct road traffic contribution to ambient NO2 has increased in recent years.

Two contributing factors have been cited

(i) Diesel vehicles emit more NOx than petrol vehicles, and with a larger proportion of NO2 in NOx.

(ii) The average value of NO2 in diesel exhaust is increasing. This appears to be linked to the growth in the use of specific after-treatment technologies in modern diesel vehicles which involve in situ generation of NO2, such as catalytically regenerative particle filters.

Background concentrations of ozone are also increasing. As the ozone concentration increases the amount of NO converted to NO2 increases.

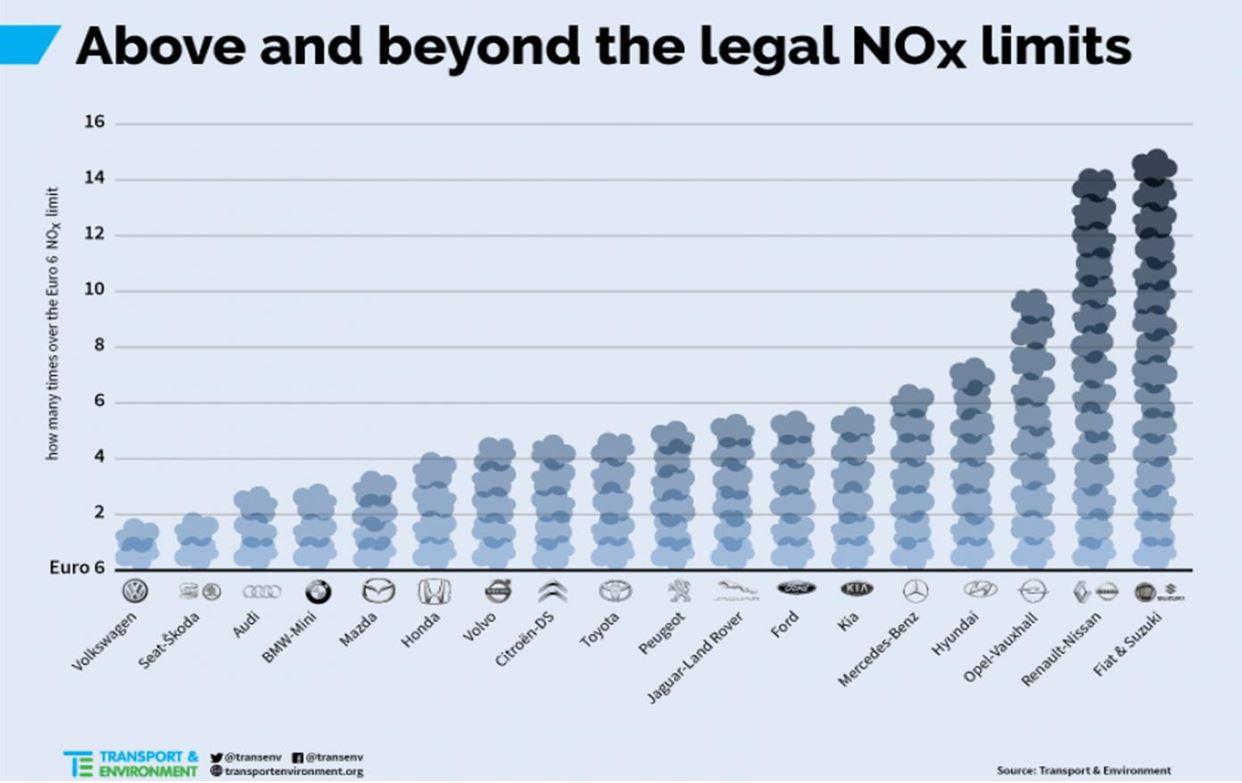

Furthermore, it seems likely that real-world NOx emissions from road vehicles are not decreasing as rapidly as models are predicting. Whilst this does not, in itself, affect actual NO2 concentrations, it does suggest that NOx controls have not been sufficiently stringent, or that vehicles are not performing as expected.

The overall consequence is that there is now a great deal of interest in the tighter regulation of NOx and NO2 emissions from diesel vehicles and the effects of different after-treatment devices. Direct-injection petrol engines with after-treatment technologies will also have an important impact on NOx emissions in the future.

Particulate matter

Epidemiological studies have shown that concentrations of airborne PM are correlated with hospital admissions and death rates. Initially, the mass concentration of airborne particles with a diameter of less than 10 μm (PM10) is identified as a key metric in relation to health outcomes. However, more recent research has suggested that smaller particles are more important. Attention has focused on particles having a diameter of less than 2.5 μm (PM2.5), although there is still a debate as to whether it is actually the mass of even smaller particles, or indeed a non-mass metric such as particle number (PN)7, that is primarily responsible for health effects. In addition to health, airborne particles are responsible for a range of other adverse effects, including nuisance and visibility reduction.

Particles in diesel exhaust have a range of sizes, and the shape of the size distribution depends on whether the weighting is by number or by mass. There are three distinct size modes: the nucleation mode (also referred to as nuclei or nanoparticles), the accumulation mode, and the coarse mode. The nucleation mode has traditionally been defined as particles with a diameter of less than 50 nm. Accumulation mode particles range in size from around 50 nm to around 1 μm, with particles smaller than 0.1 μm being referred to as ‘ultrafine’. The nucleation mode contains many more particles than the accumulation mode, although because each particle is so small the total mass is lower. The coarse mode consists of particles larger than around 1 μm.

The main implication of the particle size distribution in vehicle exhaust is that the instruments used in testing need to be sensitive enough to measure particles in the relevant size.

Regulation of exhaust emissions at type approval

The primary tool for combating air pollution from road transport is vehicle emission legislation. There are currently two main levels of emission legislation: type approval, and periodic in-service/roadworthiness technical inspection.

Emission tests are normally required for the type approval of all new passenger car (M1, M2) and light-duty vehicles (N1, N2), and for the engines used in heavy-duty vehicles. Emission limits have been applied to vehicles and engines at the type approval stage since the early 1970s. The exhaust pollutants which are regulated are CO, unburnt hydrocarbons (HC), NOx and PM. The limits have been reduced in stages since they were first introduced (through progressive ‘Euro’ standards), and changes have been made to the test methods to make them more realistic and effective. Emission-control technologies have developed accordingly.

For cars and light-duty vehicles the test procedures and limit values have been consolidated in the Euro 5 and Euro 6 legislation (Regulation (EC) No. 692/2008). In the exhaust emission test a production vehicle is placed on a power-absorbing chassis dynamometer. The driver must follow a driving cycle and the vehicle’s emissions are collected and analysed. Emissions are measured over the New European Driving Cycle (NEDC), which is composed of low-speed ‘urban’ segments and one high-speed ‘extra-urban’ segment. The vehicle exhaust gases are diluted with filtered air to prevent condensation or reaction between the exhaust gas components. Dedicated analysers are used for CO, NOx, HC and carbon dioxide8. For diesel vehicles up to and including Euro 4, PM was collected separately from the other pollutants on a filter. For Euro 5 and Euro 6 vehicles PM mass and PN are measured using the new Particulate Measurement procedure. The PN limit is designed to prevent the possibility of the PM mass limit being met using technologies that would enable a high number of ultrafine particles (<0.1 μm diameter) to pass.

Periodic technical inspection in the EU

The purpose of the Periodic inspection emission test is to allow authorities to check that in-service vehicles are well maintained and conform as far as possible to their design emission levels. However, whilst type approval tests target the manufacturer, are relatively detailed, and require specialist and expensive laboratory equipment, by necessity a lower level of sophistication applies to in-service emission tests. In-service tests target the vehicle owner, are based on shorter, simplified operations of the vehicle, involve the measurement of fewer pollutants (typically CO, HC and diesel smoke), and make use of equipment that is less precise and less expensive than that used in the laboratory.

Periodic inspections are conducted every one or two years whereas In-service inspections are designed to identify large faults rather than a gradual deterioration in the control of emissions. All types of road vehicle (passenger cars, light-duty vehicles and heavy-duty vehicles) are usually handled using similar procedures.

Petrol Vehicles

Test procedure

For petrol vehicles the first step is a visual inspection of the emission-control equipment fitted by the manufacturer to determine if it is absent, modified or obviously defective, and to identify any leaks which would affect the emission measurements.

For vehicles without an advanced emission-control system, such as a three-way catalytic converter that is lambda-controlled, after a reasonable period of engine conditioning the CO content of the exhaust gases is measured when the engine is idling.

For controlled vehicles the lambda value and the CO content of the exhaust are measured at the natural engine idle speed and at high idle speed (at least 2,000 rpm). Again, the engine is conditioned in accordance with the vehicle manufacturer’s recommendations.

No external load is applied to the engine in any of the tests.

Diesel vehicles

Test procedure

In the diesel smoke opacity test the vehicle is operated through a sequence of so-called ‘free accelerations’ with the engine under no external load, the gear lever in neutral and the clutch engaged. The inspection is done in the following steps:

On the 18th September 2015, the Environmental Protection Agency USEPA, issued a notice of violation of the Clean Air Act to Volkswagen AG, Audi AG and Volkswagen Group of America, Inc. The notice of violation alleges that four cylinder Volkswagen and Audi diesel cars from model years 2009-2015 included software that circumvents USEPA emission standards for certain air pollutants.

There is now a need for the procedures and instruments to properly measure exhaust emissions during Periodic inspections to be updated and implemented in the light of today’s technology and capability of modern measurement devices.

In Europe, there is consideration of updating their Periodic inspections due to this problem. The reality is that Australia is already consistently several years behind EU standards as the European Directive adopted the Emission Standard Euro 5 in 2011 but Australia is only up to Euro 4.

If Australia is to achieve the Australian Government’s 2030 greenhouse gas emissions target of 26-28 per cent of 2005 levels, and net zero by 2050, then the Australian Government needs to implement more stringent standards for noxious air pollutant emissions and a standards regime for fuel efficiency (CO2).

While Australia’s air quality is considered good by international standards, our increasingly urbanised and aging population may be more susceptible to the health impacts of noxious emissions. This is particularly pertinent when considering that in 2012, 66% of Australians lived in a capital city and that combined population of our four largest cities is projected to increase by around 45% (5.8 million people) to 18.6 million by 2031”.

It is imperative the Australian Government strengthens its vehicle emissions standards and practices for all vehicles, this should encompass the following key points.

Fuel standards are the obvious roadblock to implementation of Euro6, however the implementation of Euro6 vehicles with substandard fuel, would limit the available benefits, – lower fuel consumption, less toxic emissions.

In Australia, we take the manufacturers and importers word that their cars meet the emission standards. Vehicles are tested by the manufacturer in accordance with ADR’s whereas in Europe all manufactured and imported models are tested to ensure emission standards are met and are tested during their lifetime (depending on model and age) to ensure the car continues to meet the emission standard. Euro 6 emissions standards for light vehicle became mandatory in Europe from September 2014 and equivalent standards are currently in force in the US and Japan. The Euro V1 emissions standards for heavy vehicles commence in the US and Japan 2010

It is widely recognised that vehicle emission levels are affected by the vehicle condition, service history, fuel quality, vehicle usage and environmental conditions. As demonstrated by some manufacturers, the emission levels in “real world” conditions may differ from the manufacturers standardised.

Effective Emissions Testing

Test the gas efficiency of a vehicle with AutoTest’s combined AutoGas® 5 Gas Analyser and AutoSmoke® Opacity Meter. Battery operated, they measure the contents of the exhaust gas and lets you know how efficient a vehicle is at reducing the amount of pollutant gases being released into the atmosphere.